Hi folks!

Since my last post, I've been busy working on the Steam Punk Kitchen Doors. My first version, I actually liked fairly well, but not for this build. It didn't fit, as is, with the feeling I wanted this house to have. So I went back and started from scratch again. I've set aside the original door for a later project that has a little more of a cottage feel.

|

| Why didn't I see the mullion not aligned BEFORE the photo! It's fixed now! :0) |

This project was a quite complex project from the perspective of there being many steps, and took me quite a long time to figure out. I am reasonably pleased with the final results though, so it is was well worth any effort put in.

I've brought forward my concept drawing for first timers. In the last post I explained how I needed to make some simple changes due to the narrow door size I left, resulting in a basic change in the shape of the windows. However, the basic concept was still what I wanted for the kitchen doors. I have continued to modify the concept slightly here and there as I went through the process and fleshed out the design. These doors are the final result.

I thought it might be of interest to folks to know how these doors were built, so I am going to attempt to put this post together as a tutorial. My camera (definitely the camera, it could NOT be me!) still won't take decent pictures for some shots. I think I am going to have to replace it. :0(

Meanwhile, here we go on a very long post, I imagine. Hold on to your hats!

Step 1: Transfer The Pattern

Cut the door shape out of 3/32 " basswood or other somewhat soft, small grained wood. I first made a single template and drew the window shapes onto mount board, and then cut them out so that each drawing would be identical. I cut the basic rectangle(s) out of basswood prior to drawing on the door shape (in this case the window holes), and kept at it until I had four equally sized pieces.

I then drew, using the template, the base pattern on each door blank, in my case four, since I was making two doors. If you are making only one door, you will need to cut and prepare only two door blanks. You will need two door blanks for each door you wish to make.

Make sure that as you do this, you are keeping the template exactly on center, and that you keep the pencil lead close to the leading edge of the window recesses in each case, otherwise, your pattern will be in a different place on each door blank and you will get to do a lot of sanding, and perhaps even have to cut additional door blanks. The most important aspect of this step is to measure equally spaced sets of window holes on each of the door blanks, so that they can later be glued together.

Step 2: Prepare the Window Panes

Cut out the window shapes using a scroll saw. Begin this process by drilling holes into the center of each window space as seen above. This allows you to put the scroll saw blade through the hole and allows you to keep the base door shape all one piece.

Once you have cut out the windows, use heavy grit sandpaper to align the edges as perfectly as you are able to. Sand the edges of the window recesses first, ensuring that the center door post is sanded smooth, then progressing outward continue sanding and aligning the edges until all window and door edges (including outer door edges) are sanded smoothly into identical shapes.

Finish sanding can wait until the next step. For now, you are just ensuring you can eventually glue together two of the door bases and have them fit well.

Before moving to the next step, insert the door into it's door frame, and mark the location of each vertical edge against the jamb. This is the available work space to add door detail and decoration.

Step 3: Carve the Door Kickplate

Now you are ready to cut and carve the door kick plate. Begin with a wood blank. I used balsa wood on this second set of doors, in the first, I used basswood. Balsa is much easier to carve and allows for very smooth shaping fairly easily, but is so soft that I do wonder how well it will hold up. Luckily, no big people will be kicking at the door plate!

Start by cutting the wood to be carved to size. Remember to stay inside the lines you drew, as these are the edges of the door frame, and you will not be able to close the door properly if you stray over the lines.

Measure in and carve guidelines for the basic outer edge shapes of the kick plate. Here, I used a compass to create a gentle curve from one corner to the next.

Draw in and carve the door folds. Using balsa wood, I found that simply drawing my mechanical pencil carefully through the wood several times along my measured line provided me with perfectly shaped door folds. If using harder woods, you will need to use a chisel to create the folds.

Begin to shape the wood into the profile you want it to become. This process looks like you are destroying everything, but is somewhat necessary to shape the basic contour of your profile.

I used a curved gouge, a straight chisel, and a curved chisel to achieve the shapes I created. I used the gouge first, to penetrate the wood, and shape it into a very general approximation of the shape I needed. Note that I left a raised center with a very, very slightly lowered basic profile above. I then used the curved gouge to shape the upper ridge and to cut into the edges along the door folds, and to smooth out the gouged wood in the center of the door plate. I then used the straight chisel to clean out the edges along both the door folds and the upper ridge.

The next step is to sand. Using heavy grit paper, sand carefully the entire piece. You are looking for crisp edges and smoother surfaces. After you've achieved the general shape you desire, move to medium grit sandpaper, smoothing further the shapes and using the edges of the sandpaper to achieve straight 90 degree angles along the door folds and the upper ridge.

Continue sanding with fine grit sandpaper until you have a smoothly contoured surface. You should end up with something resembling the above left wood piece.

Use the newly carved blank to create a second blank. Again, remember to keep your pencil as close as possible to each edge so that you do not end up with two blanks of different sizes. However, using the first as a template helps guarantee you get exactly the same shape with both blanks. If you do get one blank larger than the other, sand to ensure that each blank is exactly the same shape and size. A little bit of variation has a lot of impact in the final picture on miniatures, so measure and compare carefully.

You can use the same technique to ensure that the folds along the bottom of the blanks are the same. I used a long ruler to align the folds on the two pieces, thus ensuring that the two door blanks have as little variation as possible.

Shape the second blank in exactly the same way as the first. Sanding is the critical step to ensure that the shapes are identical. Compare often, and adjust both carvings as needed to obtain identical shapes.

Step 4: Cut the mullions

This is the hardest step to get consistency, but with patience it can be managed. Cut mullions using a mount board template for all four mullions (for each door, a total of 8 for two). Unfortunately I do not have a photo of this part of the process. I tried, but forgot to photograph this step!

To create the template, draw the desired shape for the mullion on a piece of scrap board. I wanted the serpentine shape so common with Art Noveau, so drew a mullion shape that incorporated that feel.

It is very important to cut and then actually temporarily install the mount board mullion piece into its final home in the window. It is easy to get it too short. Do NOT use the mullion you drew in your original pattern, as it WILL be too short. Its length does not account for the cutting width of the saw blade.

Once you've measured the template and know it fits, use the template to draw 4 mullions (one for both sides and for both back windows) per door. Cut as closely to the drawn lines with the scroll saw as possible, attempting to ensure that the shape of each cut is similar. I couldn't figure out a jig for that, but if you could, that would be a good idea. I have a ways to go to learn how to think that way!

Sand your mullions to finesse the shape, again, you are looking for identical shape as much as possible.

Step 5: Sand and Stain the door pieces.

Sand all of the pieces well. I used heavy grit sandpaper first, mid grain sandpaper, then fine sandpaper, and then followed each sanding with 0000 steel wool. This provides a very smooth surface to stain.

I used Traditional Cherry wood stain which gave a deeper tone than my original door, which I like much better for my application. Note that no gluing has taken place as yet. This is because it keeps the surfaces clean and clear for the stain, and does not provide opportunity to get glue in places you don't want it. Once glue is introduced on the surface of the wood, stains are likely to highlight those areas since they coat the wood and do not allow for consistent absorption.

Step 6: Creating the Ornate Details

I used

the process I have used several times before to create details for the Steampunk doors. I found a small frame at Michael's Craft Store that I felt like had the right vibe. I've sort of arranged the "Amazing Mold Putty" molds I made near the areas of the frame I used to make the molds. The center medallion from the bottom of the frame, the additional detail at the bottom of the door from both bottom sides of the frame, and the detail at the top of the door from the top of the frame. These frames are very inexpensive, mine was about 3 dollars.

Use this process, or another process, to create details that you would like to use on the doors. One method I thought of that I knew would work was embossing paper. This was my first thought, but I could not find an embossing pattern that I liked for my Steampunk doors. I am sure they are out there, they just weren't where I was!

|

| Sorry for the picture quality~ Ouch~! |

After casting the resin molds, trim out the details that you want to use. All of my pieces started out like the large cast piece above. (Sorry for the horrid pic, I haven't figured out why some of these come out this way when most pictures are fine! I took about 15 pictures of these and THIS was the best!)

I cut portions of the patterns out that fit the portions of the door that I wanted to decorate to get my final look. Use your imagination!

Once your pieces are trimmed, paint them flat black, and then apply Polyurethane Satin Finish. I like the Minwax Water Based poly, since it is a breeze to clean up.

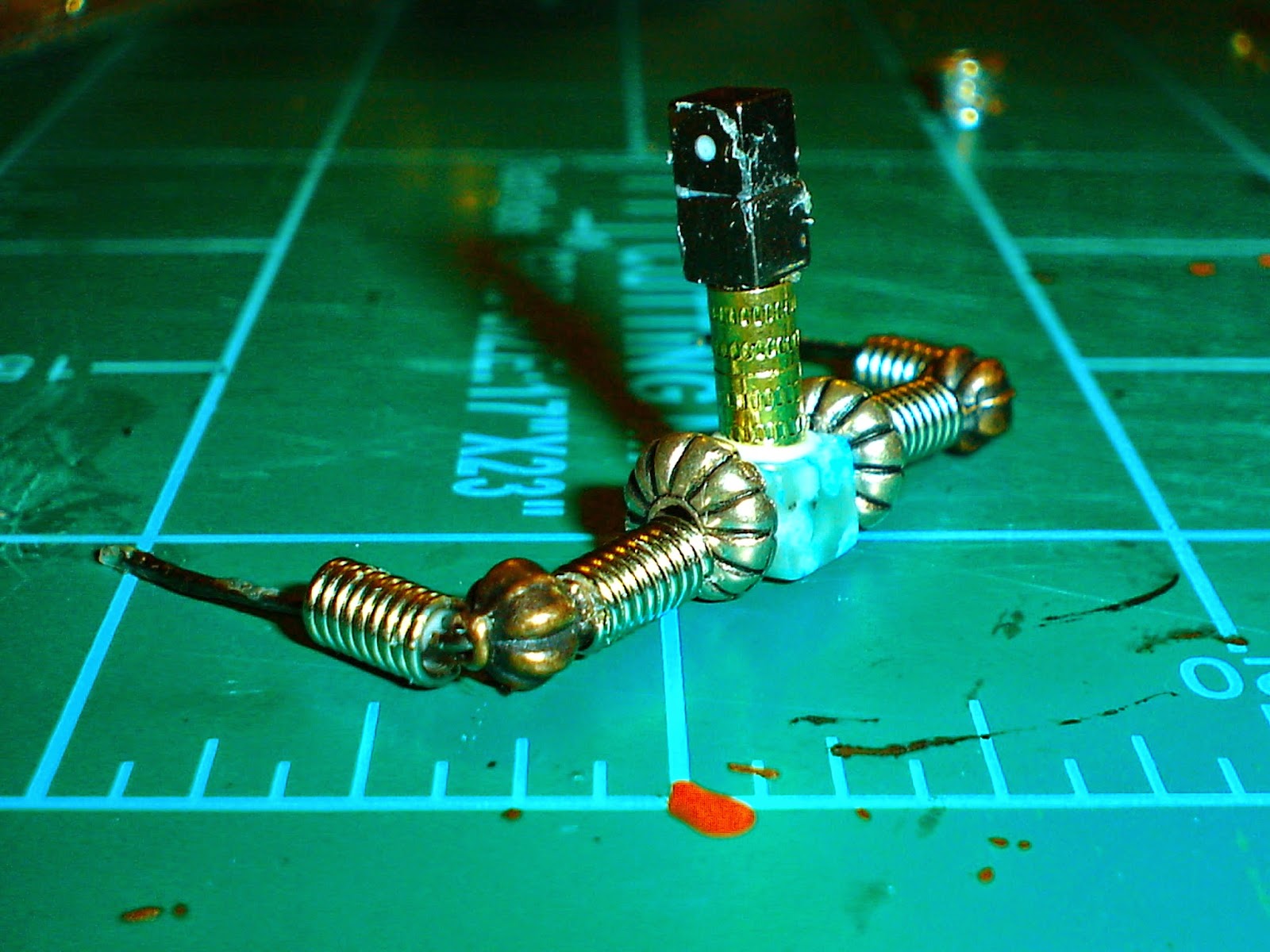

Step 7: Adding the Decorative Metal Bars

Now for the fun part! We get to begin assembling the door. Finally!

|

| More horrible pictures~ ! |

To create the decorative metal bars, I used 16 gauge wire. All you will need is a pair of wire cutters and a wire forming tool.

I will share with you that using the green wire was not my original plan, but it was a happy accident. I love it. I had originally thought I would use copper wire, but the craft store I went to was out of just about everything! So I found green wire and gold wire, and nothing else. The green was the lesser of two evils, so I bought it. Now that it is in the door, I am SO glad that happened!

To make the decorative door rods, I cut three pieces of wire for each window, and shaped them into matching gentle curves for both sides. They ranged from about 2.5 inches to about 4 inches in length.

I used a mini awl to create small pilot holes along the vertical edges and bottom curves of the windows on one of the two door pieces that make up each door. I chose to place the metal bars on the outside window surface, they could be placed on either side. This was a delicate process, but doable. I placed holes at the (reasonably) correct angle for each bar at the bottom of the window and the outside edges.

To insert the metal wire into the door frame, I chipped tiny channels into the wood to hold the wire between the door pieces. I chipped them out with a utility knife, just enough to allow the wire to sit inside the sides of the window. I placed the wire into the channels and glued it in.

Step 8: Assembling the Door

I applied the two door sides together like a "wire sandwich" with the wire laying against the acetate I used for the window, and the 2nd door piece in back of that. I glued and clamped the door at that stage, to ensure a good solid meld.

After the glue dried, I applied the kickplate to the door in its proper position.

I applied the "metal work" next, which helped me to decide exactly where to place the door mullions to look best. They are slightly lower than the original pattern, but are where I think they look best.

Step 9: Gaze lovingly at the final result.

This door was a real challenge to design and build for me, but I am quite pleased with the overall effect of the doors.

|

| Hot off the press! Glue is still drying! |

I ignored all I learned about the direction of the door swing. I played with both inside swing and outside swing, but for these doors, they just did not look proper swinging inward. So I took advantage of the occasional example of exterior doors swinging outward, and the little ones will just have to cope!

I am excited about continuing the process of finalizing design and building doors and windows for the first floor, because they add so much life to the interiors. I plan to tie in the windows along the front of the house with these doors more by adding ornate detail there as well, and the Grand Parlor at the other end of the ground floor will get windows that echo these doors. I will not be finalizing installation of any of these windows and doors until after having completed the interior ceilings, and the exterior of the ground floor.

Did I ever tell you this is fun? :0)

Hope the tutorial was informative!

Doug S